FABMATERIALS

A journey towards a tangible exploration of materials in prototyping

Materials are an essential part of manufacturing. They enable designers, artisans, architects, sculptors, and engineers to prototype their ideas. Materials impact not only the visual but also the functional aspects of a design. The process of selection and manufacturing is part of the design process which is not always considered explicitly enough. Rather then just using materials, the exploration of materials as fundamental part of the design process can create new value to the outcome. It enables us to take different positions of working on a conceiving idea, changing and potentializing novel applications in the Fab Labs.

FabMaterials is a tangible archive of applied digital and manual manufacturing processes, made primarily at FabLab Kamp-Lintfort. This analog library, accompanied by a digital resource, explores the impact of materials, their application, their modification, and their process of creation (the journey). This study has the objective of encouraging and stimulating FabLab users to discover the possibilities of exploring and promoting the incorporation of prototyping with a focus on materials research. With this experimental-driven approach, we are looking into new frontiers of prototyping in Fab Labs.

CONCEPT

A “masterpiece” is a physical object which is the result of a unique combination of design, materials and manufacturing techniques which were learned through a process of iterative prototyping. The careful documentation of these iterative explorations is the richness of the knowledge base that grows out of a FabLab.

The online version tile Fab Materials FabLab Kamp-Lintfort

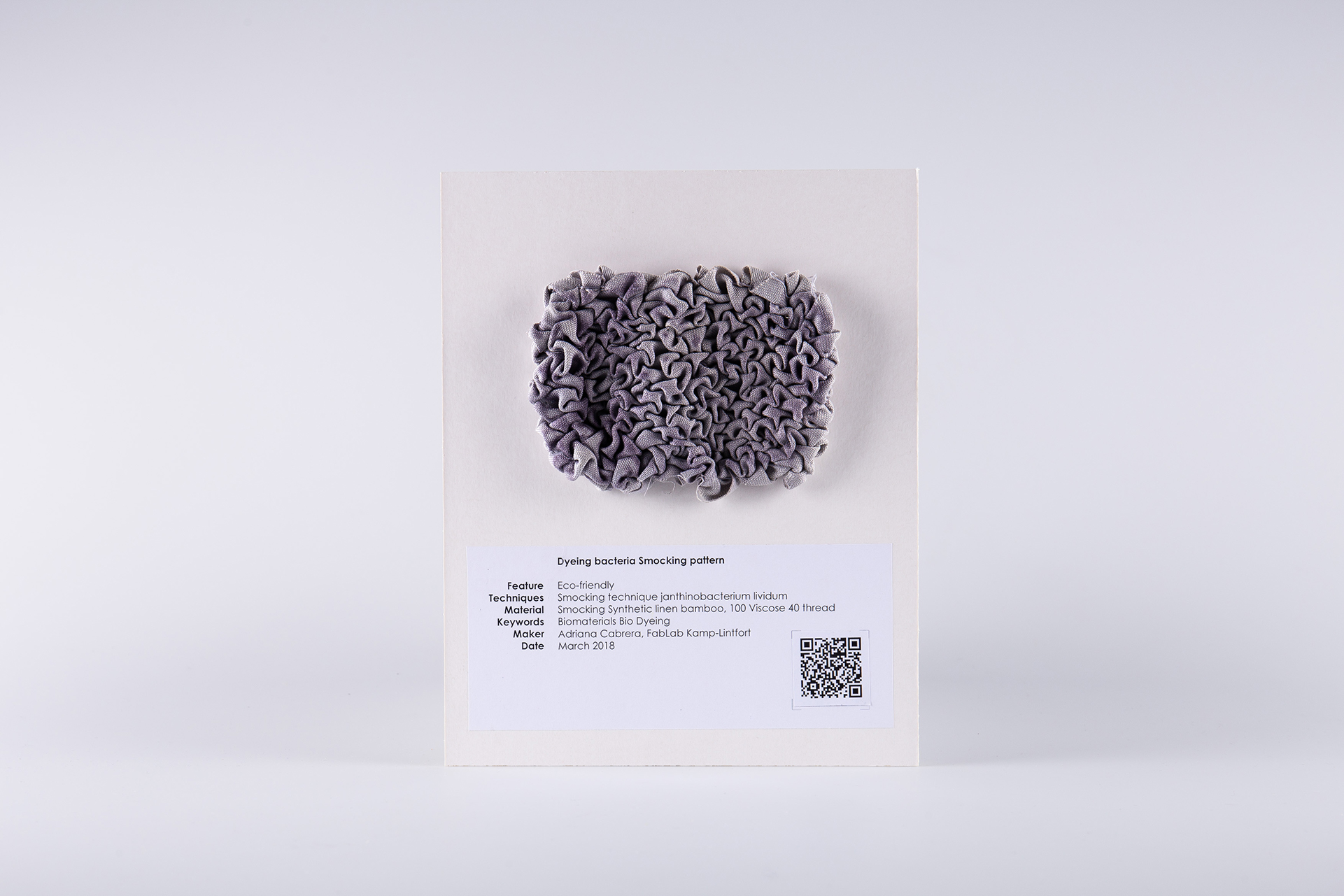

DYEING WITH BACTERIA I SMOCKING PATTERN

Main features: Eco-friendly

Techniques: Smocking technique Natural Dyeing with janthinobacterium lividum Bacteria

Material: Smocking Synthetic linen bamboo, 100 Viscose 40 thread

Keywords: Biomaterials Bio Dyeing

Maker: Adriana Cabrera, FabLab Kamp-Lintfort

Date: March 2018

3D PRINTING

MEMORY FOLDING PATTERN

Main features: Printing with thermochromic rigid material on flexible textile, create a metamaterial with memory

Techniques: 3D printing on textiles

Material: Thermochromic filament (Innofill) Lycra 100 elastane

Maker: Adriana Cabrera, FabLab Kamp-Lintfort

Date: December 2017

MATERIAL CRAFTING

Tartaric Acid Crystals

Techniques: Crystallization Scaffolding

Material: C4H6O6 Tartaric Acid Water

Keywords: Crystallization scaffolding physic process

Date: October 2017

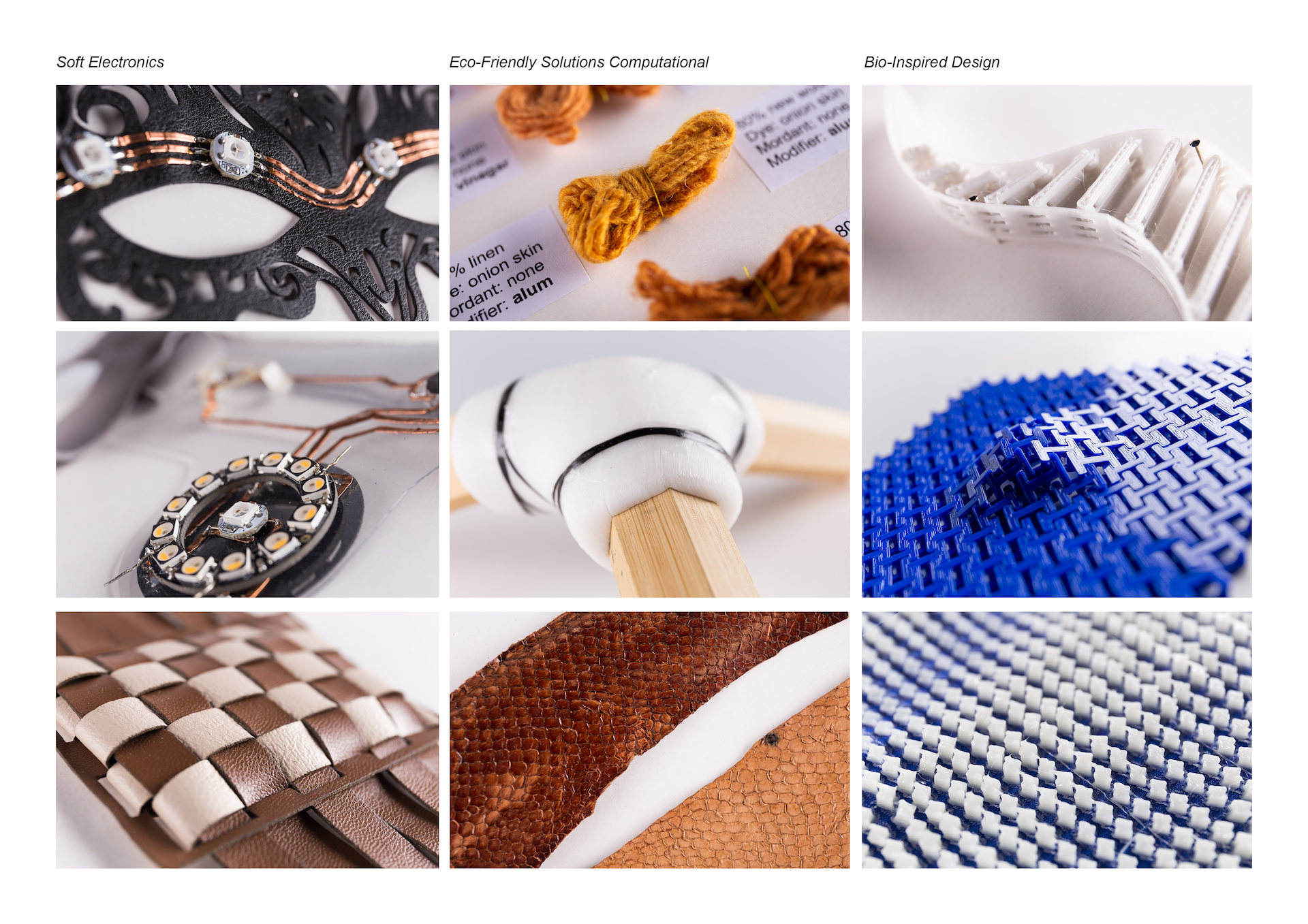

FEATURES

The relative prevalence of the main features found in the masterpieces produced in the FabLab Kamp-Lintfort since 2015

Some of the results:

biobased 9.8%

eco-friendly 6.6%

programmable 6.6%

Kinematics 4.9%

Assistive Device 4.9%

wearable features 3.3%

Locomotion- bimmimetic: 3.3%

self-assembly 1.6%

lightweight 4.9%

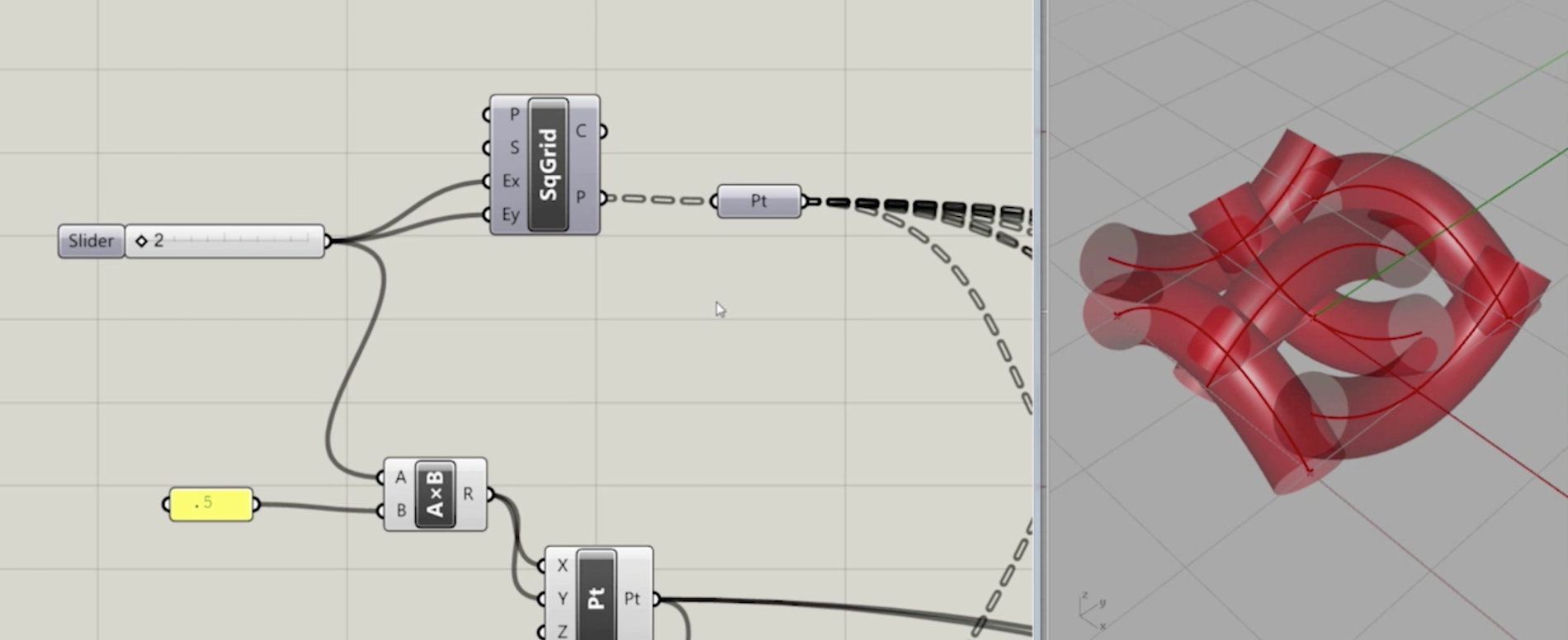

MATERIAL ITERATION

After the digital construction of a 3D fabric that can be digitally varied, the masterpiece was printed to integrate a process of textile simulation and kinematics of flexible modular parts with high precision.

The masterpiece simulated the flexibility of 3D textile printing, so this digital fabric file was used and printed on a 3D Systems printer to achieve accuracy and observe the behavior of the 3D material and construction.

With the same aim in mind, we wanted to include the processes of a second sample in which the digital file was manipulated to generate 3D weaving